How to Choose the Right Flexible Packaging Closure | Sliders vs. Press-to-Close Zippers

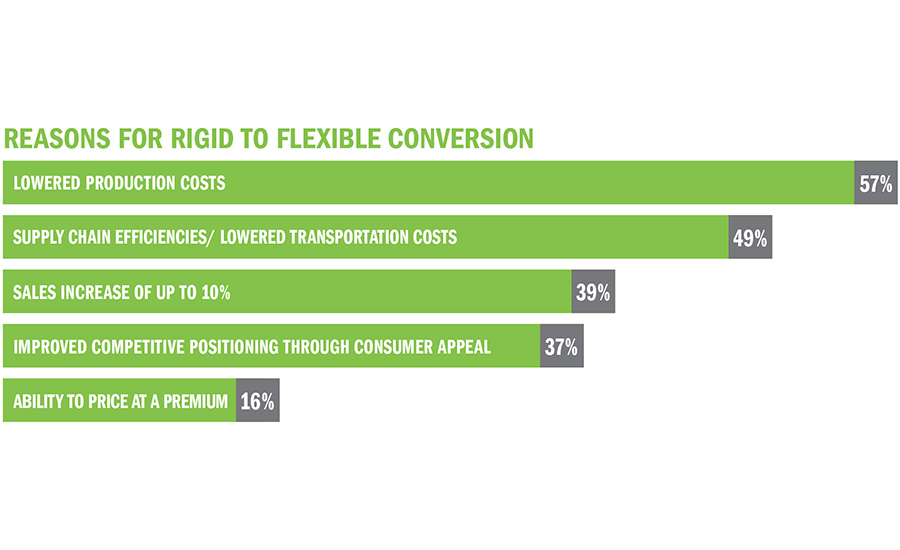

Flexible packaging is in a period of tremendous growth. Food manufacturers and brands are navigating the shift from rigid to flexible packaging and are uncovering lower overall production costs, supply chain and warehousing efficiencies, and improved consumer appeal. A survey conducted by Harris Poll shared brands’ motivations for converting to flexible packaging:

Source: Packaging Strategies, FPA survey conducted by Harris Poll

Source: Packaging Strategies, FPA survey conducted by Harris Poll

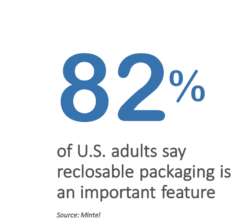

The good news is that as brands and CPGs are realizing the benefits of flexible packaging, consumers are too. One thing shoppers value most in flexible packaging is the closure and all the helpful benefits that come with it.

What Do Consumers Value in Their Packaging?

Functionality and convenience are at the top of consumers’ packaging wish list. A Mintel study found 82 percent of U.S. adults indicated reclosable packaging is an important feature, while over half of respondents (55 percent) expressed the importance of portability.

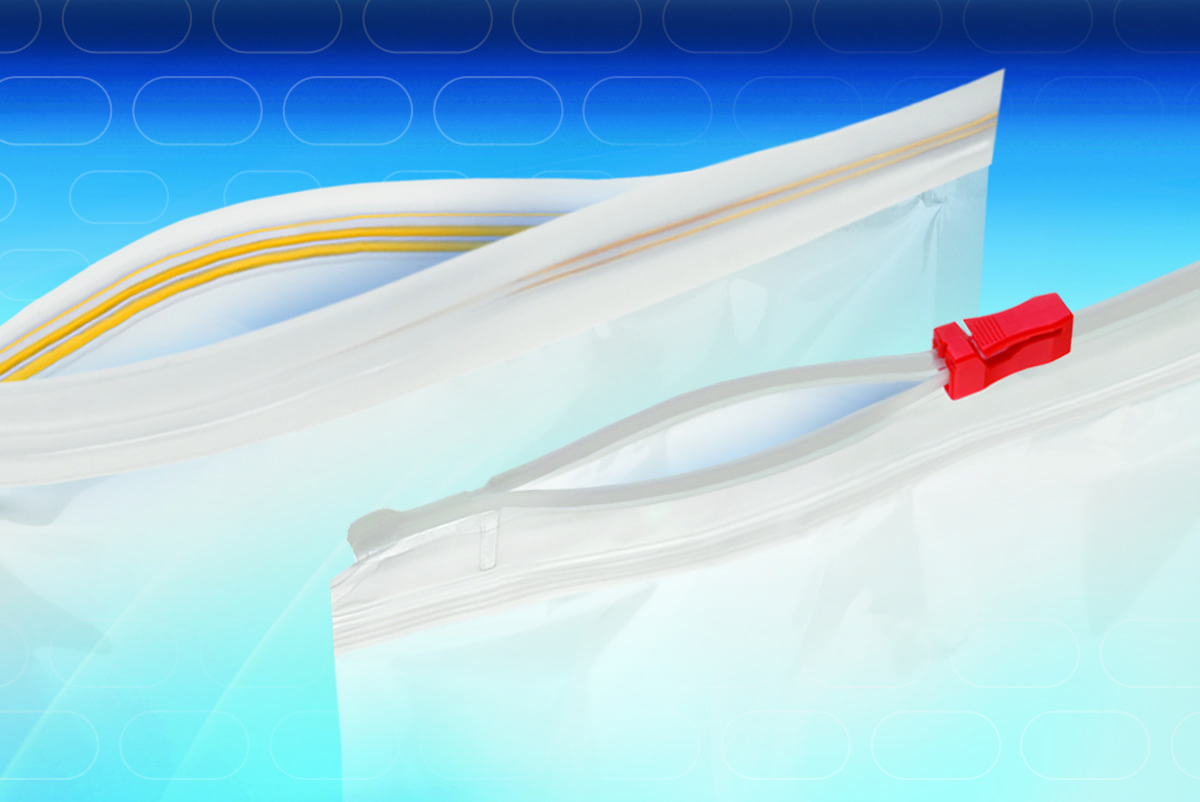

Entering the flexible packaging world requires an understanding of packaging options, which includes closures such as zipper sliders and press-to-close zippers. To create a truly well-made package, as much thought should go into what is inside the package as to what supports the product.

A package closure is one of the most crucial points of interaction a consumer has with a brand – but, they’re not all created equal. Closures can provide much appreciated time-saving convenience or sheer frustration if they don’t perform properly.

“Closures should be selected based on the ‘best fit for use’ of the package and provide an optimal consumer experience,” shares Fresh-Lock’s Senior Manager of Market Development Todd Meussling. “Whether your package is competing based on premium offerings or price alone, ensure your reclosability selection matches what your brand is trying to accomplish overall.”

A closure selection is just as critical as the selection of packaging material and graphics. Why? Closures are designed to perform in different ways, support different types of products, and solve unique pain points for consumers.

Press-to-Close Zippers Vs. Slider Zippers: What’s the Difference?

There are generally two types of closures for flexible packaging: press-to-close zippers and slider zippers. Both options are made of plastic and can be sealed into a multitude of packaging formats—everything from a small format pouch to a bulk multi-use package.

“Both applications have a shaped, extruded plastic arrowhead that connects into the opposing locking component,” shares Fresh-Lock’s Commercial Director Richard Custer. “The key difference between the two formats is how we engage with the zipper.”

The Press-To-Close Zipper

With press-to-close zippers, consumers use their fingers to pull the flanges apart and push the ribs together.

Brands looking for an economical solution that still want to offer consumer convenience often utilize press-to-close zippers. These zippers offer a balance of features and cost, while still providing extended freshness and convenience.

“The cost of putting a zipper on an on an individual package is minimal when compared to the overall cost of the package,” says Fresh-Lock’s Regional Sales Manager John Atkinson. While the cost is minimal compared to the total package cost, it adds a significant amount of value that could be the difference between a consumer selecting your product over a competitor’s.

Press-to-close zippers come in multiple variations to meet a brand’s objectives and requirements. While all press-to-close zippers can be customized for specific applications, below are some examples of where they’ve been proven to support the following products and end users:

- Double Lock Zippers provide added protection against spillage and freezer burn for frozen foods

- Thermoform Zippers provide reliable closures for processed and sliced meat products running on thermoform/fill/seal equipment

- Contaminant Resistant Zippers work well for products like spices, potting soils, and sauce mixes to ensure small particles aren’t trapped in the track during closing

- Click ‘Lock™ Sensory Zippers assure on-the-go travelers that their pouch is fully sealed with an audible clicking noise

The Slider Zipper

Slider zippers add a premium level of convenience and performance for consumers. Functionality wise, the slider piece itself directs the zipper tracks into place. It’s simply easier for consumers – plus, the slider piece forces a consumer to completely seal a package from one edge to another.

“Without a slider piece, consumers will sometimes start sealing from the middle, outwards which can potentially lead to unsealed air gaps in the zipper track,” adds Custer. “Sliders add more assurance that the package is completely closed.”

CPGs that want to provide consumers with a premium package and user experience should consider slider zippers. Studies prove that consumers are willing to pay significantly more for product attributes such as resealability, ease of storing, and ease of opening. A Harris study also shared that shoppers will pay as much as 14 percent more for packaging with reclosability. When a slider zipper is paired with the proper product, the added convenience and consumer preference outweighs package cost.

Similar to the diverse options for press-to-close zippers, sliders are also engineered to fit particular uses. While all slider zippers can be customized for specific applications, below are some examples of where they’ve been demonstrated to support the following products and end users:

- Plowing sliders remove fine crumbs and powders from the track for premium products like whey protein powders, specialty sugars or baking ingredients, or salty snacks

- Heavy products like pet food, lawn and garden products, or bulk food should utilize the S-Slider to ensure the slider can support the product weight

- Child-Guard® child-resistant sliders are of particular interest to brands that package pool chemicals, laundry detergents, and cannabis products

- Ergonomic sliders with an easy-to-grip slider piece help older users or young children who may have a difficult time pressing a zipper closed

Marketing Matters at the Moment of Truth

Without a zipper or slider, consumers must roll and crunch a package closed, use a clip or twist tie, or use adhesive of some sort. All these options are prone to opening unexpectedly and losing freshness. Introducing a zipper allows flexible packaging contents to be self-contained and keep moisture-sensitive products fresher.

At the end of the day, your package needs to sell itself on shelf. If a consumer is comparing two packages, and one has a closure and one does not, are the value-added features clear to them? Do they understand the benefit? Ensure the reclosability features are clearly communicated, whether additional graphics are added, or a clear window is featured around the closure itself.

During the final moment of truth, when the consumer is opening your package, are they delighted by the experience or frustrated that they can’t get to the product? When you work with the team at Fresh-Lock, determining the proper closure for your product that produces loyal, return customers isn’t difficult. Whether you need help simply choosing a proper package closure, or finding a co-packer to help expedite your speed to market, contact Fresh-Lock at 800-265-0750 or online to take your reclosable options to the next level.

Back to Blog

Back to Blog