Want Better Pool Chemical Packaging? Consider These 5 Things.

By 2032, the worldwide market for swimming pool chemicals is projected to reach $1.72 billion—reflecting strong and steady growth. As the market expands, manufacturers of pool chemicals face increasing pressure to differentiate their products among a vast sea of competitors.

While product performance remains critical, packaging for pool chemicals is a powerful tool that can help elevate brand value and enhance the customer experience. For producers, retailers, and consumers alike, packaging serves as more than just a container—it’s a key brand touchpoint. Traditionally packaged in rigid containers, many pool chemicals are now transitioning to flexible packaging, a modern alternative that offers benefits in safety, sustainability, and usability—while also helping create stronger shelf appeal.

1. The Consumer Experience with Pool Chemical Packaging

Because of the corrosive nature of pool chemicals, rigid pails have been the go-to packaging format for products like chlorinating tablets and water balancers. These containers can withstand corrosion while providing product protection and child resistance.

But, while rigid containers offer relatively safe storage of pool chemicals, they’re not as ideal as other packaging formats when it comes to the consumer experience. Pails take up more space than other packages, are heavy, can be difficult to open, and are not well suited for e-commerce. They’re not always air-tight, and the product-to-package ratio can mean more shifting of the product, so chlorine tablets may crumble or break apart because of repeated contact with the rigid structure.

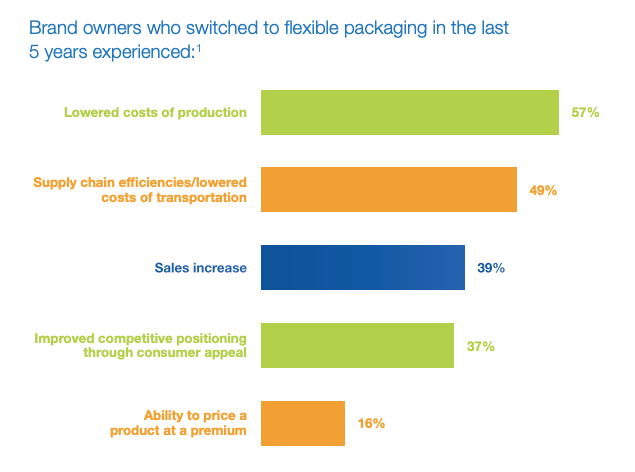

Fortunately, developments in flexible packaging films and closure technologies offer an effective solution to the unique challenges posed by traditional pool chemical packaging. Flexible packaging formats that feature high-performance films and features not only withstand the product, but protect it. The product-to-package ratio is smaller, meaning less shifting of the product. It is also more ideal for e-commerce than rigid containers, because flexible pouches take up less space, are lighter, and optimize cube efficiency—helping reduce costs and greenhouse gas emissions during transportation. In fact, in a study by the FPA, 57% of brand owners lowered production costs after transitioning to use of flexible packaging.

Some pool chemical producers have already been utilizing child-resistant flexible packaging for products like chlorine shock treatments to optimize the consumer experience. These products are largely found in single-use pouches that are opened, emptied, and discarded.

With most of the pool chemical industry opting for rigid containers or using single-use flexible pouches, you can show consumers that you’re prioritizing their experience of the product by moving to a new and improved packaging format that includes reclosability.

Adding reclosability not only helps protect the product but also makes daily pool maintenance more convenient for consumers. Like other flexible pouches that benefit e-commerce through lightweight, space-efficient design, flexible packaging for pool chemicals helps make the product easier to store, carry, and handle. When paired with the right closure, it can deliver a smooth, intuitive open-and-reclose experience—adding both function and value to the package.

2. Child Resistance is Critical for Pool Chemical Packaging

According to the CDC, pool chemical injuries account for about 4,500 emergency department visits each year, with at least one third of the patients being children under 18 years of age. With child safety a primary concern for consumers and pool chemicals regulated under both the Environmental Protection Agency (EPA) and the Consumer Product Safety Commission (CPSC) under the umbrella of hazardous substances, brands face the challenge of finding child-resistant packaging that’s also user-friendly.

Child-Guard®, a revolutionary closure that meets the legal requirements for child-resistant packaging as stated in the Poison Prevention Packaging Act, has changed the game for brands regulated by the EPA. Now, those brands have more packaging options than ever before. With a closure that passes child safety tests, pool chemical packagers are no longer limited to rigid containers. Instead, pool chemical brands can opt for flexible pouches with a Child-Guard® closure—playing a direct role in helping improve safety and keeping pool chemicals out of the hands of small children.

Learn more about Child-Guard® closures or see how they work.

3. Chemical Resistant Packaging for Pool Chemicals

Ensuring the safety and integrity of pool chemical packaging goes beyond just incorporating child-resistant closures, it also requires materials that can withstand the corrosive nature of some harsh pool products.

There are a wide variety of water treatment products that serve specific pool maintenance tasks like pH adjustment, sanitation, and algae control. It’s important that packagers recognize their potential reactivity. Chlorine-based chemicals, among others, can be highly reactive, emphasizing the need for packaging that helps prevent the risk of leaks, spills, or chemical interactions that could affect efficacy or pose safety hazards.

Polypropylene, as an example, tends to be a popular choice when designing a chemical-resistant package due to its durability and resistance to high temperatures.

4. The Retail Experience for Pool Chemical Packaging

With retail aisles and e-commerce sites lined with pool chemicals in rigid containers and tubs, adopting an eye-catching package in a unique flexible format is an easy way to get consumers’ attention and gain a competitive advantage—while also offering retailers several benefits.

Reclosable flexible packages for pool chemicals provide a unique, consumer-friendly format and a way to stand out, and with technologies like flexographic printing and digital packaging, there are more ways than ever to differentiate your pool chemical packaging in retail aisles.

Many brands commonly use unique colors and graphics to attract shoppers. Instead of branding swimming pool chemicals on circular containers, the flexible packaging configuration can allow for a larger billboarding opportunity. With large, colorful graphics and product information that consumers can see straight on, your pool chemical brand can stand out against competitors.

However, it’s also important to consider the retailer experience of your product. Flexible pouches can alleviate some of retailers’ frustrations with traditional pool chemical packaging like pails, which are heavy and take up a lot of space, both on the shelf and in storage. Utilizing a flexible packaging format allows retailers to fit more of your product on store shelves and makes restocking easier—giving them an added incentive to carry your product.

In other words, moving to a flexible format is a win-win for both your brand and the retailer.

5. Sustainability in Chemical Packaging

Sustainability is increasingly top-of-mind for consumers across industries. One way you can reach eco-minded consumers of any generation is to start with packaging. Source reduction and reuse are the current focuses when it comes to sustainability in the swimming pool chemical market.

With many consumers focused on the use of plastics, reducing the amount used in your packaging shows consumers you’re prioritizing sustainability (and their needs). Flexible packaging offers a format that requires fewer resources and provides additional sustainability benefits.

Compared to rigid containers, flexible packaging requires less plastic, water, and fossil fuels, meaning it's more sustainable. The FPA shares that a rigid pail for cat litter packaging—comparable in size and thickness to pool chemical packaging—consumes +1,429% more fossil fuel than the equivalent flexible package. The lightweight nature of flexible packaging also means fewer carbon emissions, increasing its overall sustainability. That means you can show consumers you’re not only reducing plastic, but also working to reduce energy consumption and your carbon footprint.

Once you have made the switch from rigid to flexible packaging for your pool chemical products, you can further improve your brand’s carbon footprint by looking at material selection. Closures made with post-consumer recycled (PCR) content align with the most-preferred principles in the Waste Management Hierarchy—reduction, reuse, and recycling. Recent updates to our award-winning Child-Guard® Track and Slider technology reflect the Fresh-Lock team’s ongoing push toward sustainability. Now featuring at least 25% PCR content in the Child-Guard® track—and we’re just getting started. Our goal is to increase that percentage even further, all while delivering the same trusted performance necessary for your pool chemical packaging.

By integrating PCR materials into your flexible pouch, you can help reduce demand for virgin resin, conserve resources, and lower energy use in material production—all while contributing to a more circular package for pool chemicals.

Reach More Customers with Resealable Flexible Packaging

With new packaging technologies at our fingertips, it’s time to evaluate how we can innovate packaging design to provide added value to customers, whether manufacturers, retailers, or the end consumer. Get in touch with the Fresh-Lock team to learn more about options available based on your products and needs or get more insights on packaging for the pool market here.

This blog was originally published on 7/13/2020 but updated and republished on 6/30/2025.

Back to Blog

Back to Blog