Sustainability From the Start: Flexible Packaging Design for Powdered Goods

Sustainability in flexible packaging doesn’t start at the recycling bin—it starts at the design table. True environmental impact is shaped not at the end of a package’s life, but at the very beginning, with every material choice and structural decision. While end-of-life is important, the most powerful lever for sustainability is smart design from the start.

Designing for sustainability means packaging engineers, designers, and consumer-packaged goods (CPG) brand managers should make intentional choices about what their packaging solutions will be from the beginning. By looking beyond recyclability or compostability, packaging suppliers and brand owners have an opportunity to collaborate on solutions that are efficient, functional, and environmentally responsible. This early collaboration is key to embedding sustainability into every stage of development.

So, how do we focus on sustainability from the start? It begins with a shift in mindset—when we focus on keeping materials in use for as long as possible, we not only want to support initiatives like recycling, but we also want to prioritize the reduction of virgin material use, find ways to reuse flexible packaging materials, and incorporate renewable materials.

Smart packaging design involves removing what isn’t needed and optimizing what is. It also means engineering packaging that is as sustainable as possible, even if it isn’t disposed of under ideal conditions, especially given the limited availability of recycling and composting infrastructure.

Bottom line, the earlier sustainability in a reclosable flexible pouch is considered, the greater the impact it can have.

Flexible Packaging vs. Rigid Packaging: A Lower-Impact Format for Free-flowing Products

For dry flowables like mixes, protein powders, or baking products, reclosable flexible packaging offers a clear sustainability advantage over rigid packaging formats. Flexible packaging typically uses significantly less material, which helps reduce the overall weight of the package and lowers transportation emissions. Flexible packaging formats also take up less space during storage and distribution, improving efficiency throughout the supply chain. When thoughtfully designed, reclosable flexible packaging can still offer the necessary protection to help maintain freshness and prevent food waste—while using fewer resources and supporting a smaller environmental footprint.

When a flexible pouch is made with recyclable, bio-based materials and closures, flexible packaging becomes an even more compelling choice for sustainability.

Rethinking Dry Goods Packaging Materials with Recyclable, Bio-Based Materials

While traditional polyethylene (PE) is derived from petrochemicals, bio-based recyclable PE is made from renewable sources like sugarcane or other plants. It’s a little poetic—your brand’s sugar pouch could be made from sugarcane. Sweet, sustainable, and smart by design.

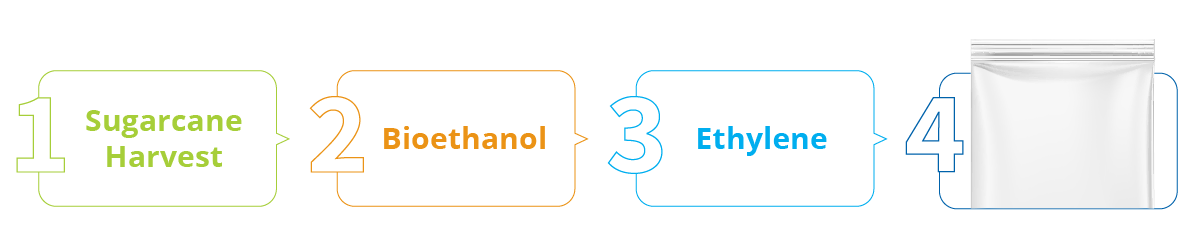

Take Fresh-Lock® Renewables+ Style 8041B, our first bio-based recyclable, particle-resistant press-to-close zipper optimized for powdered goods. It all starts when sugarcane is fermented into bioethanol, which is then converted to ethylene and polymerized into PE resin. The result? A polyethylene that performs exactly like its fossil-based twin—but with a lighter environmental footprint.

The key advantages of bio-based PE include its renewable source, the carbon-absorbing lifecycle of the plant it all started with, and the compatibility with existing recycling infrastructure.

An important distinction to understand is that bio-based PE is not biodegradable. Its end-of-life disposal method is identical to traditional PE—it must be recycled properly, or it becomes waste, like anything else that goes to landfill. As long as this messaging is well communicated to the consumer, bio-based PE helps dry goods brands take a more proactive approach to environmental responsibility.

Functional Performance Meets Sustainable Materials with Mess-Resistant Packaging for Powders and Granular Particles

Even as we continuously seek new ways to innovate and advance sustainability in the flexible packaging industry, the Fresh-Lock team understands that sustainability can’t come at the expense of performance.

Powders and dry goods present unique packaging challenges. Products like flour, sugar, spices, and pancake mixes have traditionally been packaged in paper bags that can shed or leak product and often lack proper seals against air, moisture, or pests. Beyond these general concerns, each type of dry good has its own specific needs. For example, sugar’s fine granules can often interfere with reclosure mechanisms, while powdered milk is highly sensitive to moisture and requires a secure, airtight seal. Bulk spices need packaging that preserves their aroma, flavor, and freshness, and pancake mixes—which often contain multiple ingredients—demand all these protections to maintain quality.

When packaged in reclosable flexible packaging, these granular products can get stuck in the zipper or slider, making it difficult to properly open and reclose. Fortunately, our particle-resistant zippers feature anti-clogging locks for smooth, clean zipper performance.

With the right closure, protein powders, instant coffee, dried soups, hot cocoa mixes, and other powdered goods can be securely closed–giving consumers confidence that their favorite fine, dusty, and granular products will remain fresh use after use. Specifically, Fresh-Lock® Style 8041B delivers a clean, consistent reclose every time, helping reduce product waste, enhancing the user experience, and minimizing frustration that could otherwise lead to repackaging or disposal of a product.

Scaling Sustainability, One Step at a Time

Bio-based, recyclable materials are a game-changer for sustainable packaging—though they do carry a premium over traditional PE today. Brands can ease into this shift by piloting line extensions or blending bio-based content with conventional resins. These incremental moves allow supply chains and recycling systems to mature in parallel. Strong partnerships and collaboration across suppliers, converters, and brands will be key to driving scale, reducing costs, and unlocking long-term value for everyone in the value chain.

If you’re exploring ways to incorporate a bio-based, recyclable, particle-resistant closure into your package, contact the Fresh-Lock team today.

Back to Blog

Back to Blog