Finding Flexibility in the Pool Chemical Market with a Child-Resistant Slider

Industries across the board are taking advantage of the benefits and efficiencies flexible packaging has to offer – and, the numbers speak for themselves. Brand owners who have switched to flexible packaging in the last five years lowered production costs by 57 percent. Flexible packaging is not only favored by brand owners but consumers as well: when given the choice between the same product in a non-flexible package, 71 percent of consumers said they preferred the flexible packaging option (source: FPA)

Until now, the options for packaging multi-use, reclosable pool chemical packaging has been, literally, quite rigid. Today, pool chemical products on the market that require child-resistant packaging will be found packaged in rigid containers with child-resistant lids.

New developments in child-resistant closures for flexible packaging create an alternative to what was once the one-and-only option in the pool chemical market.

Flexible Efficiencies

When compared to rigid packaging, the benefits of flexible packaging are frequently described as highly efficient.

As we know, flexible packaging uses less material than rigid containers. It is not only a source reduction alternative, but positively impacts issues associated with warehousing and transportation. In fact, brand owners who switched to flexible packaging in the last five years have seen supply chain efficiencies and lowered transportation costs of 49 percent. Imagine how much space empty rigid pails take up in a warehouse compared to flattened, unfilled pouches.

The possibilities of flexible are wide-ranging. Instead of branding products on circular containers, various flexible packaging configurations allow larger billboard branding opportunities. In a recent study, 55 percent of brand owners indicated they saw a sales increase from making the transition to flexible.

Success in SUDs

Products like individual detergent packs, or SUDs (soluble unit doses), are already taking advantage of these benefits.

Early on when the detergent packs first launched, children were getting into the packaging and were accidentally consuming the laundry packs. However, with the addition of Fresh-Lock’s Child-Guard®, a child-resistant closure designed for reclosable flexible packaging, laundry packs can now be safely packaged in flexible while also meeting the criteria for child resistance.

“Child-Guard® opens up new avenues for markets with regulated products or products that could be potentially harmful if children were to access them,” says Todd Meussling, senior manager of market development at Fresh-Lock®. “We quickly discovered the need for this in other markets, such as pool chemicals.”

Possibilities for Pool Chemicals

All of this points to a new path for the pool chemical market. Tom Morsheimer, technology business development and sales representative at Fresh-Lock®, explains, “These products are regulated under the Consumer Product Safety Commission and the EPA, so brands are compelled to be in child-resistant packaging. Until the development of Child-Guard®, multi-use flexible packaging wasn’t even an option.”

“As we know, pool chemicals have traditionally been packaged in rigid tubs or single-use flexible pouches,” says Meussling. “The industry has been limited to use that type of packaging for years. A reclosable, flexible package is finally an alternative option that can provide significant benefits and efficiencies.”

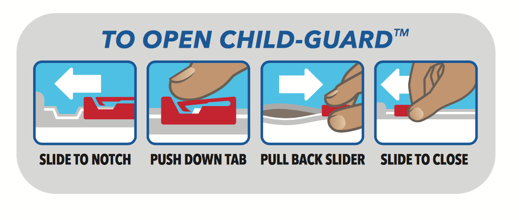

To open the child-resistant slider, adults push down the slider tab into the notch and then pull the slider across the zipper. To get the full benefit of the sliders safety features, it’s important for people to close the package fully to ensure it locks in place. What’s more, tests indicate that the necessary requirement of children under the age of five were unable to open the closure, even after being shown how to open the bag.

Meussling and Morsheimer comment that while it’s not limited to these products, they see two primary possibilities for pool chemicals in the reclosable flexible packaging market: shock treatment and chlorine tablets.

Right now, chemical shock is packaged in a single-use flexible package or rigid container. Chemical shock could move into multi-application flexible packages. In addition, chlorine tablets are packaged in heavy rigid tubs and could benefit from a multi-use reclosable package, as well.

Next Steps Towards Child-Resistant Packaging

Thanks to Fresh-Lock’s innovative child-resistant closure, flexible packaging is a definite possibility and natural progression for the pool chemical market.

For brands interested in this opportunity, Meussling indicated that it will be important for Fresh-Lock® to “understand the company’s go-to-market strategy, positioning, product mix, and identify what products would lend themselves to a good transition into flexible.”

“We’d then look at the current packaging used and measure it against a transition to flexible. From there, we’d examine the current process; the challenges in the current manufacturing and product requirements as we go through packaging qualifications; and then prototypes with customer and film suppliers to identify the best package for the application,” adds Meussling.

To take the next steps in making your brand and operation more flexible, contact Fresh-Lock® by Presto Products Co. to learn about how Child-Guard® could work for your product.

Back to Blog

Back to Blog