Choosing the Right Packaging Type for Your Meat Products

With more meals being prepared at home, the significance of packaging in shaping consumer choices cannot be overstated. This is particularly true for processed meats such as hot dogs, sliced deli meat, and similar products, where packaging can play an even more pivotal role. In 2023, U.S. Meat Department sales were more than $122 billion—up more than $39 billion from 2020. To keep up with this growing demand, meat brands and packagers can benefit from embracing effective and efficient flexible packaging solutions.

Two questions commonly asked by the meat industry: what packaging materials are available for different types of meat products and what benefits do these packaging solutions bring to my operation and consumers? The answers to these questions depend on the unique goals and requirements of each meat product. Below, we outline how meat brands and flexible packagers can collaborate to find tailored solutions that fit their needs.

Extending Shelf Life: The Role of Film Materials and Closures for Meat Packaging

With all meat product types, whether fresh, frozen, or pre-cooked, the right packaging film material and compatible closure can help maintain the quality of the product. When used in combination with proper refrigeration or freezing, flexible packaging can provide a strong moisture and oxygen barrier that helps extend the shelf life of meat products. Once the package is opened, a reclosable zipper can help maintain the moisture barrier so the meat product can be consumed in multiple servings. In addition to finding a packaging type that is suitable to your meat product’s specific requirements, it should also provide a positive experience for the consumer.

For instance, if you offer a high-end deli meat at a premium price, the consumer expects a premium package and closure that will match that meat product’s quality and help maintain its freshness. Consumers should expect to have the same experience with the meat product every use, even after multiple times opening and closing the package. A quality zipper or slider on a package can help preserve freshness and reduce potential leakage from the meat products.

The Fresh-Lock® Multiplex Zipper Style 8555 is a closure style that offers a variety of attributes beneficial to certain meat packages. This innovative closure features an easy open and close experience that consumers can hear and feel, as well as five sets of interlocking channels that help seal in freshness, unlike other “hook and hook” style closures, which allow air to pass through. Multiplex is compatible with a wide range of film structures including recyclable polyethylene, and works well with a variety of pre-made or horizontal pouch making equipment.

How Meat Products Are Packaged

The same way proper film materials and closures are important for helping extend product freshness, the packaging method for meat products plays a direct role in the efficiency of a meat packaging operation. Two widely used packaging technologies in the processed meat sector are thermoform packaging and form, fill, and seal systems. Each of these packaging methods offers unique advantages depending on the type of meat product.

Thermoform packaging uses heat to mold a plastic film into a custom-shape, allowing the meat product to rest securely in the flexible format. After the meat is added to the package, a top film is sealed over it, under vacuum or gas flushed creating an oxygen deprived environment. These methods are well-suited for modified atmosphere applications, which is common for fresh and processed meats like premium cuts, portion-controlled servings, hot dogs, pepperoni, salami, and smoked meats.

Form, fill, and seal pouch packaging, on the other hand, is favored for its efficiency and versatility in high-volume operations. For this packaging type, flexible film is formed into a pouch, filled with the meat product, and then sealed—all within a single, continuous process on the line. Form, fill, and seal packaging is adaptable to a wide range of ready-to-eat meat product types, like frozen chicken cuts and jerky snacks.

Infrastructure Considerations for Meat Packaging Materials

The Fresh-Lock team understands the significance of an efficient packaging operation: the product must run fast on lines with an optimized operating window, the zipper must seal well with films and structures, and there must be no leaking or loss of atmosphere from the finished package.

To understand what meat packaging materials will work best for your packaging operation, your current equipment and capabilities must first be assessed. Are you using a thermoforming process or a form, fill, and seal pouch making system? What is the intended design of the package? The right packaging partner will ask you these questions to make the best recommendations for your needs.

For operations using vertical form, fill, and seal equipment, our Fresh-Lock® Pre-Zip closure is pre-applied to rollstock and designed to seamlessly work with existing converting equipment with little to no modification. Pre-Zip provides a broader operating window than comparable products for greater flexibility across a wide range of applications. The flat sealant layer enhances sealability and compatibility to various films, allowing you to keep the packaging materials that work best for your meat products.

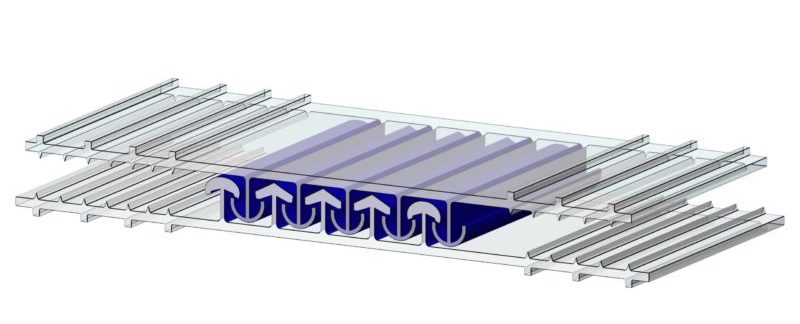

Fresh-Lock® Thermoform Zippers are specially designed to meet the challenges of the thermoform process often used for processed meats, such as pre-packaged sausage and sliced deli. Our thermoform zippers are made with special blends to provide consistent sealing, reliable side seal crush, and diminished puckering of the film and distortion of graphics. Plus, given their flexibility, our thermoform zippers feed smoothly into the equipment and can be customized to your brand’s aesthetic and appearance—helping you portray a better-looking package for your retail deli and meat case applications.

While each of our meat packaging closures can offer many benefits on the process side, an improved consumer experience is what will truly drive brand loyalty.

Enhancing the Consumer Experience with Premium Packaging Solutions for Meat

The reclosable packaging market is poised for significant growth from 2024 to 2031, largely fueled by increasing consumer demand. Reclosability is a pivotal feature offering the advantage of preventing product leakage or breakage.

According to the USDA, it is oftentimes safe to freeze meat within its original packaging. Despite this fact, many consumers still choose to repackage their meat products due to a lack of confidence in the reusability of the original packaging. By repackaging their meat products, the consumer seeks to maintain product quality, prevent freezer burn, and access the product over multiple uses. Reclosable flexible packaging can reduce this process to help keep the meat product in its optimal condition, combat food and packaging waste, and keep important brand and product information with the consumer.

Meat packaging that uses closures adorned with tear bead designs like Fresh-Lock® Zipper-Top can support the meat package's hermetic seal compared to perforated options. This helps defend against excess oxygen and moisture transmission due to the perforations, which can contribute to the product's quality over time. Moreover, integrating reclosability into the meat packaging adds convenience while instilling confidence in consumers, assuring them of the package's integrity prior to purchase.

Finding the Right Packaging Materials for Your Meat Products

Frozen, deli, and processed meats each need to be packaged correctly to maximize their flavors and prevent moisture loss—all while keeping the consumer in mind. Packaging your meat products with innovative closures will leave a lasting impression, while reinforcing brand quality and benefits.

If you do not see a reclosable flexible packaging option that fits your needs or don’t know what would work best with your meat product, contact the Fresh-Lock team today, and we can collaborate to develop the best solution for your needs.

This blog was originally published on 06/29/2021 but updated and refreshed on 8/12/2025.

Back to Blog

Back to Blog