Press-to-Close Zippers for Meat Flexible Packaging | Make the Right Choice

Reclosability can add significant value to flexible packaging. Flexible pouches with closures are regularly used in both retail and food service applications for frozen, heat-and-eat, and deli meat products.

However, there are some challenges within the meat packaging environment that require unique solutions to ensure efficiency in manufacturing and effectiveness in functionality.

At Fresh-Lock®, we’ve made it our mission to design and develop improved closures for meat packaging. Regional Sales Manager, John Atkinson, and Market Development Manager, Todd Meussling, helped explain how we’ve approached the challenges.

How to choose the right flexible packaging for meat products.

“We asked the same question about our zippers for meat packaging that we do with all our products, and that is ‘How can we make this better for this type of package?’” Meussling says.

Meussling tells us that learning how to improve reclosable flexible packaging for meat products started with talking to key players in the industry.

“We spoke with several meat processors to ask them what they liked and disliked about the closures they were using,” he says. “We found a lot of the issues were related to process limitations in making a package that performs well.”

“We also reached out to several manufacturers on the equipment side of the industry and trialed our zippers to get their feedback,” Atkinson adds.

Problem Solving Meat Zippers

One aspect of meat packaging that differs from the way a product such as cookies might be packaged are the packaging requirements. Thermoform package processing of most meats is a high performance process, which takes place in a low temperature environment. Seal integrity of the package is paramount in order to maintain freshness through the product shelf life. Fresh-Lock® set out to engineer closures designed to run on thermoform machines that meat processors could rely on.

“After conducting many tests, we found that not only did our closures meet our customers’ expectations, they exceeded them,” Meussling says. “That’s because we were able improve the packaging operating window and reduce zipper related waste”

Atkinson expands on that, describing how the benefits Fresh-Lock® offers are centered around the “machinability” of our zippers. These closures are designed to allow packaging engineers to explore a variety of film material options without worrying about whether the zipper application will be problematic.

“Because of the composition and design of the zippers we produce, we’ve been able to show good results early in the qualification process,” he says. “What they find is there’s a better end crush-seal, which means fewer leakers, which leads to less scrap. Overall it works better for the meat packer.”

The thermoform zippers Fresh-Lock® offers are made to satisfy the high-performance necessities of meat packaging, including standard zipper sizes.

“You need zippers that perform, and we take the next step.” Atkinson says. “Fresh-Lock® can bring different features that will be attractive to the consumer while remaining within the constraints of our customers’ current packaging processes.”

For example, our meat zippers are made with resins that can help avoid the unattractive puckering of the film and distortion of graphics. That’s complemented by a better-looking side seal, which helps portray a better-looking package.

Adding Value While Minimizing Cost

Atkinson says a lot of the changes and trends in meat packaging are driven by requests coming from brand owners who are heavily influenced by what consumers desire and demand.

Statistics show shoppers significantly prefer reclosability on flexible pouches. In fact, they expect it. Atkinson believes the low cost of adding a zipper to a meat package should not be a deterrent.

“The cost of putting a zipper on an on an individual package is minimal when compared to the overall cost of the package,” he says. “Film type and graphics for example, come into play a lot more than the zipper does, but the zipper adds greatly to the perceived value.”

Of course, some would point out that the cost becomes much greater if you’re doing a run involving millions of packages. Yet, Atkinson is confident the cost of zippers can be absorbed.

“Consumers are going to choose convenience over a small price difference almost every time.”

Atkinson is correct. Studies indicate consumers will pay significantly more for certain product attributes, of which reclosability as well as related benefits rank near the top of the list. In fact, a Harris survey suggested shoppers will pay as much as 14% more for reclosability.

While the cost for adding press-to-close zippers is usually lower compared to applying a slider as the closure for flexible packages, Meussling thinks there could be room for sliders to serve as a first-class option in certain situations.

“We have seen increased interest in premium closures such as a slider for certain applications,” he says. “I wouldn’t be surprised if sliders appear more frequently in the meat case.”

Find the Right Closure for Meat Products

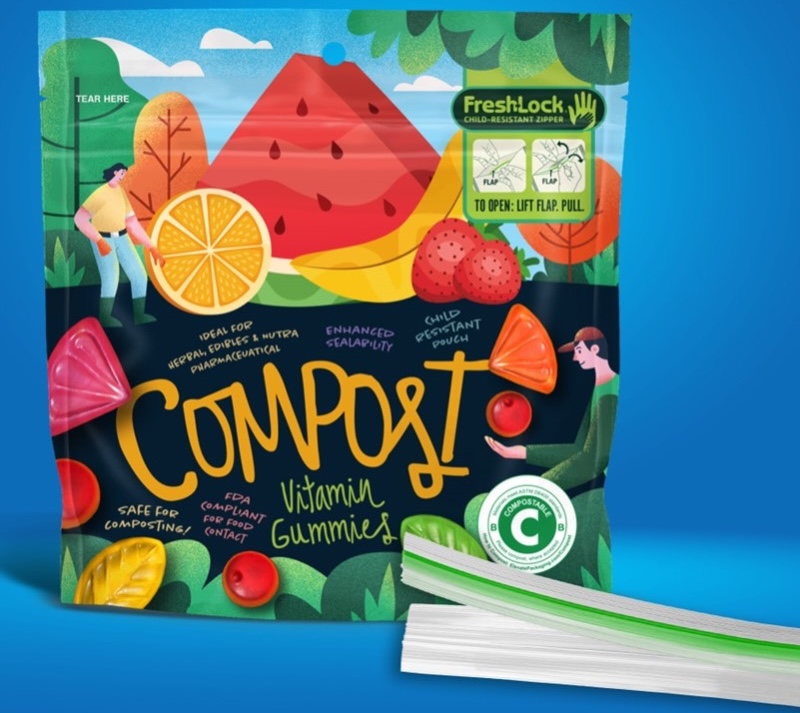

Fresh-Lock® has a variety of closure solutions for flexible packaging, including press-to-close zippers that can be manufactured to work effectively on thermoforming machinery.

Zippers with Soft Seal® are made with material requiring less energy to machine, so converters can achieve high-quality crush seals without sacrificing cycle rates.

Ribbed zippers are compatible with most packaging films and provide for reliable zipper to film seals on most horizontal and vertical form, fill, and seal equipment.

Our DZ (Double) zipper gives consumers convenience and confidence with a better grip and tactile feedback upon closure. Similarly, our Click ‘N Lock™ sensory zipper provides audible feedback, letting consumers know a meat package is securely closed to retain freshness.

Have questions about any of our products? Contact Fresh-Lock® today for answers or reach out directly to a sales rep in your region.

Back to Blog

Back to Blog