How Reclosable Flexible Packaging Can Support a Circular Economy

As brands continue to pursue ways to achieve improved sustainability by changing their manufacturing processes, making environmentally-conscious packaging decisions, and taking a closer look at the entire supply chain, questions start to arise.

Where are the best places to focus sustainability efforts? What actions will have the greatest impact? How can brands effectively communicate with consumers to ensure end users do their part to complete the cycle?

There are increasing efforts being taken by manufactures to set goals of ensuring less plastic becomes waste by eliminating unnecessary materials, making more plastics reusable or recyclable, and ultimately keeping plastics in the economy and out of the environment.

Sustainability and the Circular Economy

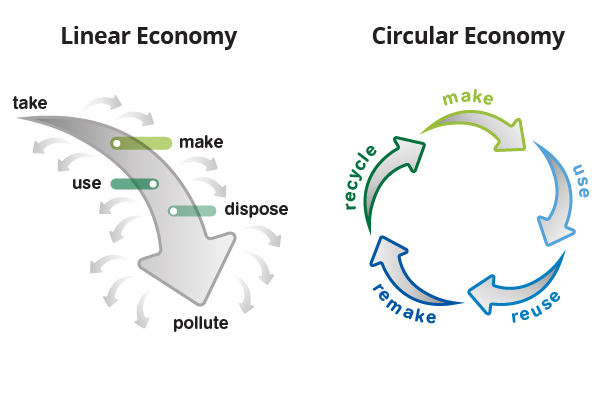

The circular economy is a concept that first emerged in the sixties, but has been refueled by proponents such as Dame Ellen MacArthur, whose foundation is directly connected to the New Plastics Economy initiative.

Put simply, a circular economy (or circularity) concentrates on reducing waste and maximizing opportunities to make the most out of the resources we use every day. A circular economy stands in contrast to a linear economy, which involves taking, making, using, and disposing, creating waste that can pollute the planet. Circularity, on the other hand, designs the waste out, so resources can be regenerative and restorative.

MacArthur is retired from a record-breaking sailing career, but launched her foundation after witnessing the amount of plastic pollution in the ocean firsthand. She and others believe sustainability efforts that support a circular economy not only help the environment, they can also lead to positive business outcomes.

In fact, the 2012 report, Towards the Circular Economy, commissioned by the Ellen MacArthur Foundation and conducted by McKinsey & Co., estimated a subset of manufacturers in Europe alone could see upwards of $630 billion in cost-savings from sustainability efforts.

To achieve improved sustainability and experience those benefits, however, brands and manufacturers must first evaluate the entire lifecycle of a product, including its packaging.

More About the Circular Economy

Flexible Packaging and the Waste Management Hierarchy

As consumers, we’ve all been hearing about the three Rs – reduce, reuse, and recycle – for years. But many of us don’t realize that these three methods have different purposes to support circularity and sustainability.

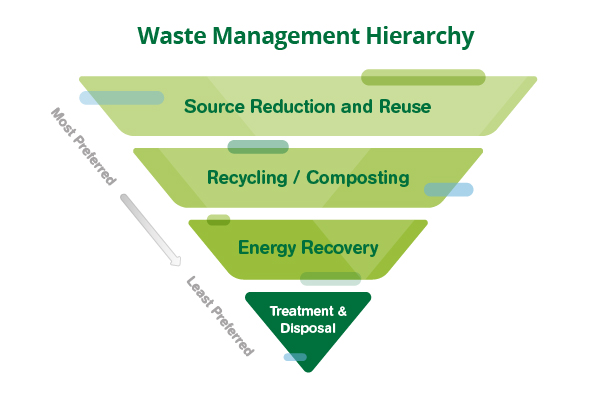

The U.S. Environmental Protection Agency (EPA) developed what it calls a waste management hierarchy for sustainable materials management, which can be used to prioritize manufacturing efforts.

As the inverted pyramid below indicates, source reduction and reuse as well as recycling and composting are most preferred, while energy recovery and treatment and disposal are at the bottom of the hierarchy.

Let’s start at the bottom and take a closer look at these methods as well as what brands and manufacturers should consider when it comes to sustainable product packaging.

Treatment & Disposal

If materials such as packaging do end up in landfills, there are steps that can be taken to reduce their environmental impact by limiting the toxicity and volume of the waste. If there is less packaging waste ending up in landfills, and the materials are less likely to harm the environment, that’s a good thing.

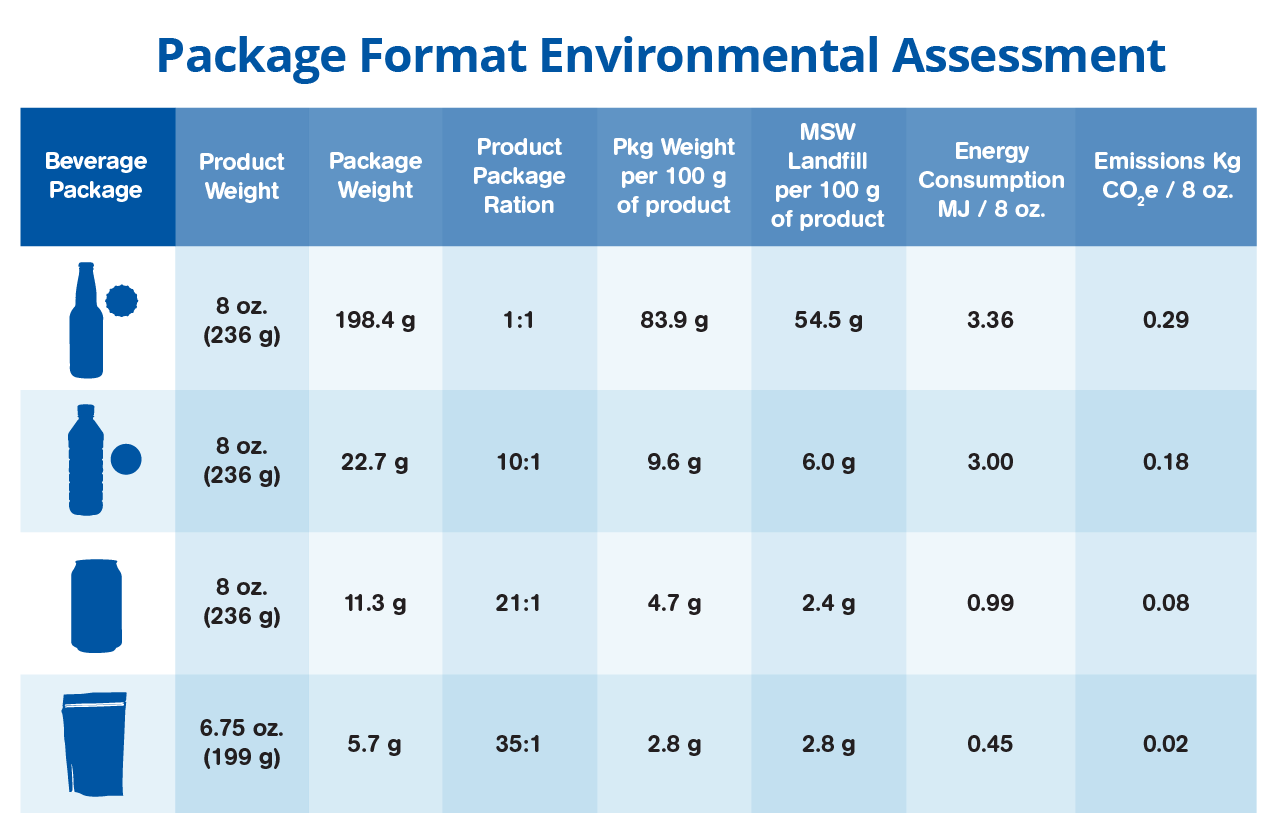

Waste reduction is one reason why flexible packaging is more sustainable than rigid plastic. As the Flexible Packaging Association (FPA) often points out, flexible films have a higher product-to-package ratio, which reduces the amount of material required to create a package, meaning less plastic waste ends up in the landfill. So, a good first step for brands is moving from rigid to flexible packaging.

Of course, this tactic is at the bottom of the waste management hierarchy. And, since waste ultimately ends up in the landfill, technically, it does not support a circular economy.

Energy Recovery

There can be opportunities for manufacturing operations to use non-recyclable waste as a way to produce energy such as heat and electricity. Through waste-to-energy (WTE) processes such as combustion, gasification, anaerobic digestion, and landfill gas recovery, manufacturers can offset their carbon footprint.

For example, Plastic Packaging Facts explains that modern facilities are taking advantage of plastic-to-fuel technologies that can convert packaging material into alternative fuels. It also says energy recovery could prevent as much as 40-million metric tons of greenhouse gases from entering the environment.

There are existing programs that get consumers involved in energy recovery. For example, the Hefty® EnergyBag®program allows consumers in select North American communities the opportunity to fill an orange bag with hard-to-recycle plastic waste, including candy wrappers, chip bags, and juice pouches. These bags are placed in recycling bins and the waste is transformed into fuel at energy recovery centers.

Energy recovery is certainly more circular than sending waste to the landfill, but there are still other ways to support a circular economy.

Composting

Composting presents another unique opportunity for sustainability. While not all plastic packaging is compostable, certified compostable plastic packaging can break down in the right conditions, eventually returning to soil. There are also bioplastics, which are derived from renewable resources and leave a potentially neutral or negative carbon footprint.

Compostable packaging, however, still isn’t completely circular. That’s because waste still ends up in the landfill. It’s not designed to break down in a consumer’s backyard compost pile, and it’s not a method that puts waste back into the economy for a specific purpose.

Recycling

It’s easy to understand how recycling supports a circular economy. Recyclability allows for a regenerative product lifecycle as materials go back into the supply chain.

In many cases, consumers are considered the main touchpoint for recycling plastic waste. Research shows sustainably-minded consumers will look for products and packaging made from recycled material, and they’ll be more likely to purchase items in plastic packaging that’s easy to recycle.

However, not all recycling takes place on the consumer end. For example, the Fresh-Lock® green spool program allows packaging converters and other manufacturers to send plastic zipper spools back to be broken down and turned into new spools, preventing them from entering landfills. The Fresh-Lock® brand even covers the costs of return shipping for the used spools.

In the past, achieving recyclability with flexible packaging was somewhat of a challenge due to the multiple layers used to create films. However, great strides are being made in this area. Read the story of the fully recyclable Bear Naked® granola pouch to learn more. It explains the packaging partnerships needed to achieve a more sustainable standup pouch, including the use of recyclable closures from the Fresh-Lock® 8000 series.

Unfortunately, making a package recyclable doesn’t guarantee it will get recycled. The New Plastics Economy states that only 14 percent of global plastic packaging is recycled. That’s why an important step towards circularity is consumer education. In the U.S., those efforts are being led by the How2Recycle® program, which offers special labels for compatible plastic packaging as well as drop-off sites at a growing number of participating retail locations.

A promising emerging technology is chemical recycling. While traditional plastic recycling involves breaking down material into pellets, which can be used to form new products, chemical recycling goes further. In this case, plastics are broken down to their molecular level. So they can be reused as basic chemicals or polymers for new plastics. This process could be useful in recycling a more complex stream of flexible films.

Source Reduction

One of the preferred options in the EPA’s waste management hierarchy is source reduction, which means eliminating waste at the start of a product lifecycle by using less raw material.

Source reduction in packaging presents a major opportunity for CPG brands, and it’s a benefit that flexible packaging has long provided. Not only is less material used to produce the package, the lightweight format also means less energy is needed to manufacture the packaging and there is a reduction in carbon emissions from transportation in comparison to rigid plastic.

The table below from a Flexible Packaging Association (FPA) report on source reduction shows how a standup pouch compares to other types of packaging.

To further support source reduction efforts, the Fresh-Lock team developed a reduced scale closure called the Fresh-Lock® mini Slider, which is an ideal solution for small format pouches.

Reuse

The basic difference between reusing and recycling is that reuse involves continuing to use an object for its intended purpose while recycling involves breaking an object down into raw material that can be transformed into something new.

The Fresh-Lock® green spool program offers an excellent example of reuse in the packaging supply chain. Not only can used zipper spools be recycled, depending on the industry/facility, spools can also be shipped back to be washed and reused without needing to be broken down and reformed. That’s circularity in action.

This is an even better solution than recycling, since less energy is required to put the spool back into the production cycle. Packagers who participate in spool reuse even get credits toward future purchases.

On the consumer end, reclosable flexible packaging can often be reused to store other things. Plus, reclosable features on flexible packages greatly reduces food waste.

Take the Next Steps Toward Sustainability

If you’re determined to improve sustainability efforts around packaging, start by looking for source reduction opportunities. That may initially entail switching from rigid to flexible packaging.

If you want to offer flexible packaging that is recyclable, you’ll also need to find the right partners to help make every component on the package compatible. The Fresh-Lock® team has the connections, the insights, and the solutions to help brands and converters take action on sustainability.

Learn more when you view our exclusive on-demand webinar, Growth in Green: Opportunities in Sustainable Flexible Packaging. Or, contact the Fresh-Lock® team today.

Back to Blog

Back to Blog