From Trash to Treasure: The Rise of Home Compostable Packaging

As consumers continue to consider the impact their purchases have on the environment, they are increasingly choosing products with sustainable packaging. This demand has led the packaging industry to advance quickly, working together to make a wide variety of sustainable avenues more accessible to brands. From traction gained by bio-based materials to recycled plastic being reused to create new packaging components, consumer packaged goods (CPG) brands are actively transitioning from legacy formats to more sustainable alternatives.

While existing barriers like infrastructure limitations could stall further buy-in of compostable packaging, the looming long-term ramifications of pollution, landfill overcrowding, and eventual regulations and fines highlight the importance of continued innovation. Collaboration between brands, non-governmental organizations (NGO’s), and government entities works to fuel the progress toward enhancing the viability of compostable packaging, which would typically result in increased availability and affordability.

As of 2023, the global compostable flexible packaging market was valued at $1.26 billion and is expected to surpass $2.11 billion by 2032. To keep this momentum on track, raw material suppliers are addressing the lack of commercial compost facilities by developing solutions which can meet requirements for home compostable packaging, taking matters into their own hands to help reassure consumers.

Home Compostable vs. Commercially Compostable: What’s the Difference?

Compostable packaging refers to packaging materials specifically designed to break down under biological conditions into a soil amendment. Flexible pouches and closures designed for composting are comprised of various renewable sources like bio-based plastics, paper, or other biodegradable polymers.

Unlike traditional packaging materials, compostable packaging degrades by utilizing microbials, moisture, oxygen, and heat. This type of environment allows the microbes to break down the materials resulting in a biomass, leaving no plastic residue behind. This makes compostable packaging a great sustainable alternative to legacy formats, offering CPG brands the opportunity to reduce their environmental footprint by minimizing waste and supporting a circular economy.

Within the genre of compostable packaging, two established pathways exist, each requiring unique characteristics.

Commercially Compostable Packaging

Commercial composting, also known as industrial composting, operates on a larger scale than at-home composting. Industrial composting sites typically collect compostable materials like food waste, directly from bulk supply sources including municipalities, institutions, sports venues, and more.

Once the compostable materials reach a composting facility, various methods can be employed for the composter to actively monitor and manage the process to ensure effective and complete biodegradation on a commercial scale. Factors such as carbon and nitrogen ratios, microbial populations, temperature, moisture levels, and pH are closely monitored to produce compost that adheres to regulatory standards.

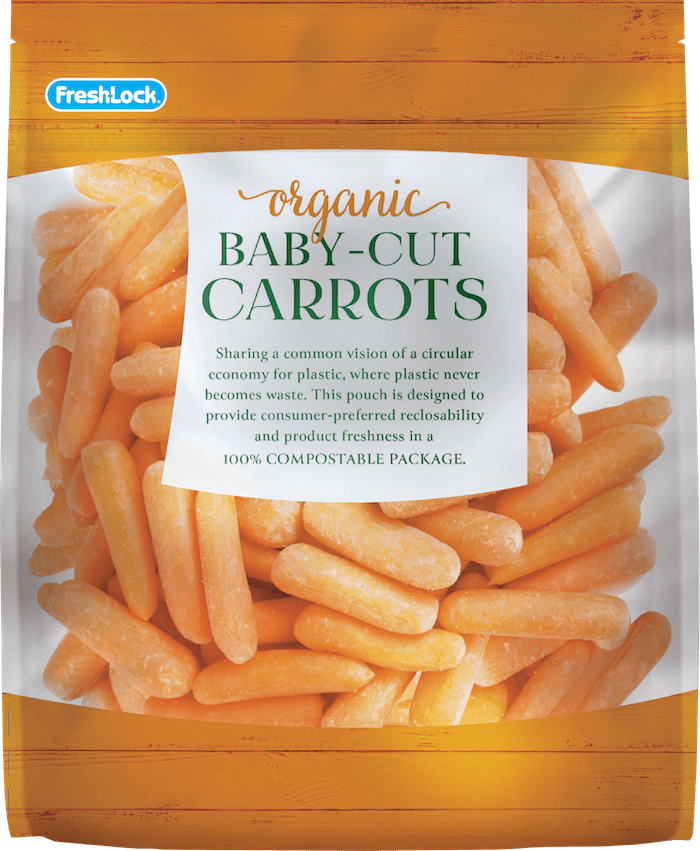

Bio-based packaging, including industrially compostable zippers created by the Fresh-Lock team are a great option for brands that want to create a fully compostable, reclosable pouch as they seal to a range of compostable films at low temperatures. These closures are FDA approved for food contact applications and are designed for consumer convenience and product security. A commercially compostable closure can please sustainability minded consumers in more ways than one.

Home Compostable Packaging

While there are several established commercial composting programs, the infrastructure available to the individual consumer is limited. This can be especially frustrating for consumers who purchase a product because of the positive impact of the packaging, only to find that a viable recovery stream is not available.

While the packaging industry waits for industrial composting infrastructure to expand, home compostable solutions offer a forward-thinking alternative, by using a very old, but proven method. Home composting, also known as residential or backyard composting, is the same process on a smaller scale. Consumers will often create a compost pile or invest in a compost bin where they can keep the biodegradable materials moisturized, aerated, exposed to natural heat, and accessible to microbials.

When composting is done at home, the decomposition timeline can vary from two weeks to two years, depending on key factors including climate and materials. With our home compostable closure, Fresh-Lock® Style 8531, materials are tested to biodegrade under compost conditions within 180 days. This child-resistant, press-to-close zipper was designed in collaboration with TIPA, a global leader in compostable packaging solutions, to produce a fully home-compostable pouch. Once decomposition is finished, consumers can utilize the resulting compost to enrich their gardens.

The Role of Consumer Education in Embracing Compostable Flexible Packaging

Since compostable packaging requires specific compost conditions to properly biodegrade, it’s vital that consumers understand where and how they can dispose of a package.

Despite the good intentions of brands adopting compostable packaging, without accessible or properly understood recovery streams, these packages may still end up in landfills. Even though some bio-based materials could decompose in landfills, the process of burying a package restricts the biological conditions necessary for the package to break down.

To address this, consumer education is key. Clearly labeling packages as commercially compostable or home compostable and providing instructions on how consumers can facilitate decomposition at home or where to find a local composting agency can help ensure those materials never have to see a landfill.

Explore Compostable Closures for Your Packaging Needs

Compostable packaging is rapidly growing, and we are excited to have solved the reclosability gap with both industrial compostable and home compostable options for flexible pouches. Compostable materials can perform well with many applications, but they are ideal for food based, non-toxic products that don’t require high barrier requirements or an extra-long shelf life. Our compostable closures are made using certified materials, such as vegetable oil, sugar cane, stover, straw, dent corn, and hemp. Market support of packaging made from these resins allows packagers to utilize renewable resources and produce high-performing products designed to return to the soil and thus kept out of the landfill.

If you’re interested in learning more about compostable closures, or you’re still trying to determine if a compostable pouch is the right fit for you, our team and network of pouch converters can help you decide. Contact the Fresh-Lock team today and see how you can offer a sustainable, reclosable pouch that delivers the ideal consumer experience.

Back to Blog

Back to Blog