Closure Spool Handling: A Guide for Seamless Production

While choosing the right closure for your flexible pouch is key to providing a positive consumer experience, we also want to ensure that your team has a smooth and efficient production process. From the moment our spools leave our facilities to their integration on your flexible packaging production lines, every step of handling plays a crucial role in maintaining product integrity and delivering a positive user experience.

Proper Closure Roll Handling: From Delivery to Production

Our closures are shipped to brands and converters on large plastic spools that are designed to facilitate easy feeding into packaging equipment for application to flexible films. From the moment these spools are packaged and transported, how they are handled and oriented becomes paramount to ensure seamless production.

Upon receiving your shipment, it is crucial to meticulously inspect the roll for any signs of damage. If any damage is observed, promptly report it to your Fresh-Lock® customer service representative.

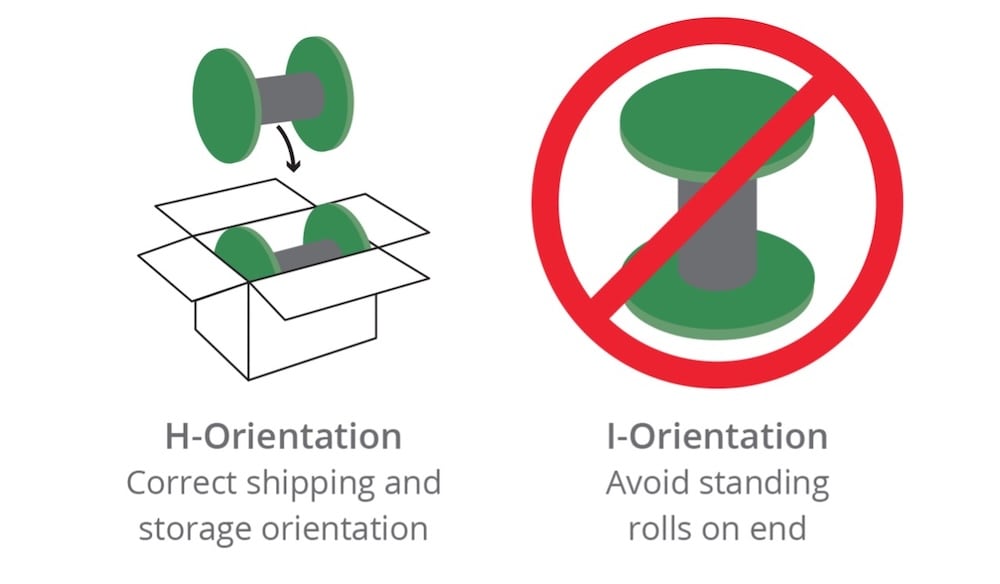

The spools are shipped in the “H” position, with both flanges supporting the core. It is imperative that the spool never be placed in the "I" position, where one flange rests firmly on the ground with its opposite side vertical to it. If the spool is placed in the “I” position, the closure wrapped on the spool has a greater chance of shifting or overlapping, potentially leading to operational issues such as jamming or snagging during machine use.

When your team is ready to thread the closure spool, it is important to exercise caution when opening the shipping box to prevent damage to the closure. Adhere to your workplace’s protocols and safety measures when using tools like box cutters to carefully release the tape and open the package. Once the package is opened, gently tilt the box forward and guide the spool out of the box.

After carefully positioning the spool onto the unwind, remove the stretch wrap before threading the machine and engaging the drive pins. To remove the shrink wrap, pull it off by hand perpendicular to the roll. Avoid using a blade, as it may risk damaging the closure.

With the shrink wrap removed, proceed to thread the machine following these steps:

- Carefully cut the tape securing the zipper and pull out enough closure to begin threading it into the machine.

- Slide the spool into place, ensuring the drive pins are engaged. Place the safety collar and leave it in position.

- Now, you are ready to make the splice and thread the closure into the machine.

Best Practices for Storing Closure Spools

In addition to safe handling, proper storage of Fresh-Lock® closure spools is essential to maintain their quality and performance. Follow these guidelines for optimal spool storage:

- Keep Closure Spools in Original Packaging: Spools should remain stored in their original package until they are ready to be used. This helps protect them from potential environmental factors and ensures they stay clean and undamaged.

- Store Spools in a Controlled Environment: Manufacturers should store Fresh-Lock® closure spools in an area with controlled environmental conditions. For optimal storage and product maintenance, keep spools in an area with relative humidity levels between 10 and 75% and a temperature range of 0 to 120 degrees Fahrenheit (-18 to 49 degrees Celsius). This controlled environment helps preserve the integrity of the closures.

- Adhere to Recommended Conversion Timeline: For closures components made from extruded plastic, like Fresh-Lock® Slider Tracks and Fresh-Lock® Zippers, we recommend converting within two years from the date of manufacture. As such, Fresh-Lock® closures are backed by a warranty that extends up to this two-year limit, ensuring reliability and performance within this timeframe. For Fresh-Lock® Sliders, which are crafted from molded plastic, we recommend use within one year from the date of manufacture. Our warranty coverage for sliders also extends up to this one-year limit.

Following these storage guidelines will help ensure that Fresh-Lock® closures maintain their quality and perform optimally when used in packaging applications.

Supporting Your Sustainability Scorecard With the Fresh-Lock® Green Spool Program

The Fresh-Lock® Green Spool Program embodies our dedication to sustainability and circularity within the packaging industry. Through our Green Spool Program, we offer converters and brands options for spool reusability and single-use recyclability.

Converters and brands participating in the Green Spool Program have the opportunity to return spools to Fresh-Lock® for reuse instead of sending them to landfills. This initiative is facilitated by our modular spool design, which can be easily disassembled and returned in their original shipping cases. By simply pulling the Cord-Lock, the single-use spool can be broken down into nested components, which are then repacked separately into their original shipping boxes. Upon arrival at our facility, returned spools undergo inspection and washing before re-entering the supply chain. In cases where spools cannot be reused, the material is recycled into new single-use spools, ensuring minimal waste.

To further incentivize participation in this sustainability-minded program, the Fresh-Lock team covers the cost of shipping the used spools back, making sustainability the convenient choice for manufacturers. This not only helps reduce greenhouse gas emissions but also contributes to manufacturers’ sustainability scorecards at no additional cost. In fact, for every spool we can wash and reuse, manufacturers receive a $1 credit, encouraging ongoing participation in the program and fostering a culture of sustainability within the industry.

Your Impact Counts: Work with Fresh-Lock® for a Greener Tomorrow

Since the launch of the Green Spool Program, Fresh-Lock® has helped save millions of spools from landfills. Our commitment to reducing waste and promoting circularity in the flexible packaging industry remains steadfast. For further information about our sustainable flexible packaging closures, or to learn more about proper and safe handling of our spools, contact a Fresh-Lock representative today.

Back to Blog

Back to Blog