3 Ways New Slider Insertion Transforms the Reclosable Flexible Packaging Industry

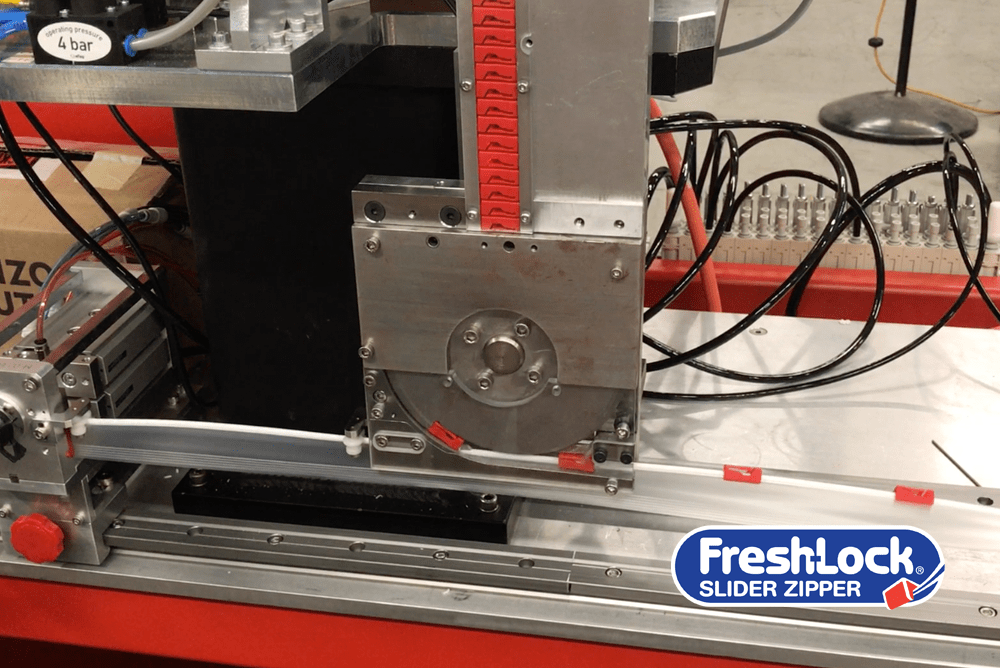

Your business is always on the lookout for new methods of becoming better, faster, and more efficient than your competitors. We’re excited to introduce new technology that maximizes operational efficiency: Fresh-Lock® rotary over the top insertion, or ROTI.

This enhanced slider insertion process offers the following:

- Increased speed & flexibility

- Reduced complexity

- Improved registration

- New packaging possibilities

Want more details? Read on:

1. Easier, speedier insertion

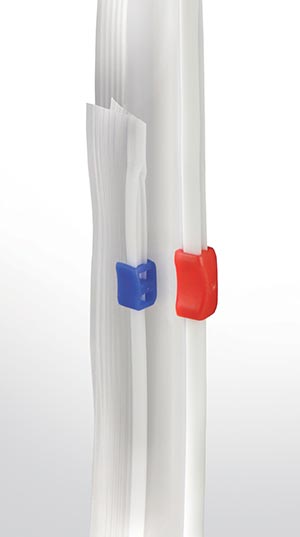

ROTI was designed to make insertion easier and engineered to run significantly faster than traditional insertion methods. Rotary over the top insertion is designed for various slider types, including the Fresh-Lock® mini Slider and Child-Guard® child-resistant slider.

The compact system can function intermittently or continuously, whereas traditional insertion systems can only run intermittently. Rather than the slider being inserted in the dwell phase, it can be inserted in dwell or during motion, even to the point where the process can run in continuous motion. To do so, the slider progresses around a rotor and is placed over the track, versus being placed in a notch and then the track progressing through the slider.

For the mini Slider specifically, the equipment can produce substantially more packages per minute (ppm) than traditional technology, turning out 200 ppm in intermittent mode and 500 ppm in continuous mode.

Imagine how much extra output your operation could produce with just a few minutes of extra time.

The flexible process also allows controls to be adjusted as needed. The system can run as simplex, duplex, or triplex.

2. A system anyone can run

ROTI is simple to run, operate, and maintain due to its smaller footprint and fewer moving parts. The slider insertion component can be added and integrated within existing machines so there’s no additional standalone machinery required.

Simpler manufacturing means less time spent training, fewer technical hiccups, and more staff with the ability to operate machinery.

Additionally, the ROTI method allows for a larger processing window. A larger processing window yields fewer processing issues, which in turn, delivers track and sliders more reliably and helps prevent costly defects.

3. Fail-safe registration

With ROTI, punch size is eliminated or drastically reduced.

Unlike traditional notched or slit insertion methods that rely on significant interference during threading or insertion, rotary over the top insertion has limited to no interference with the track. During the threading or insertion process, any changes in interference or friction can cause detrimental registration issues. By placing the slider over the track, registration is drastically improved.

For you, better registration reduces waste in your plant and ensures a smoother insertion process.

Insert ROTI’s benefits into your operational process with Fresh-Lock

Ready to boost consumer satisfaction, reduce operational complexity, tackle registration, and speed up your overall process with ROTI insertion?

Contact the Fresh-Lock® team today today to get the conversation started. We’ll help you uncover and address total cost saving efficiencies in your plant with consumer-favorite sliders for flexible packaging like Child-Guard® and the mini Slider.

Back to Blog

Back to Blog