Helping Reduce Waste with Frozen Food Packaging

According to the National Resources Defense Council (NRDC), approximately $165 billion worth of food gets tossed each year due to passing expiration dates and loss of freshness. By 2030, Boston Consulting Group estimates that annual food loss and waste will hit $1.5 trillion. Meanwhile, consumers look for ways to manage their food supplies and reduce waste however they can.

A 2017 survey found that frozen food purchases were on the rise, citing that 32% of shoppers were expecting to purchase more frozen food because it doesn’t spoil as quickly as fresh food, helping them save money and reduce waste. Unfortunately, saving and waste reduction isn’t a guarantee when buying frozen foods.

With frozen food, waste is based largely on faulty or insufficiently sealed packaging. Regardless of the expiration date, exposure to the elements inside a freezer can negatively affect food. Closure failure, closure uncertainty, and resulting freezer burn often cause consumers to toss exposed food; waste which could be eliminated with more reliable frozen food packaging closures. For consumers, wasting food equals money lost. And when looking at the global impact of food waste, the dollar amount is growing substantially. While this increasing amount of waste seems daunting, those within the food supply chain can help reduce it.

The BCG study states, “Companies that play a major role in the food value chain, in particular, can be catalysts for change.” For frozen food packagers, using more reliable closures can help. In conjunction with flexible packaging, the following options are a win-win for food waste reduction and consumer benefit.

Closures for Food Waste Reduction

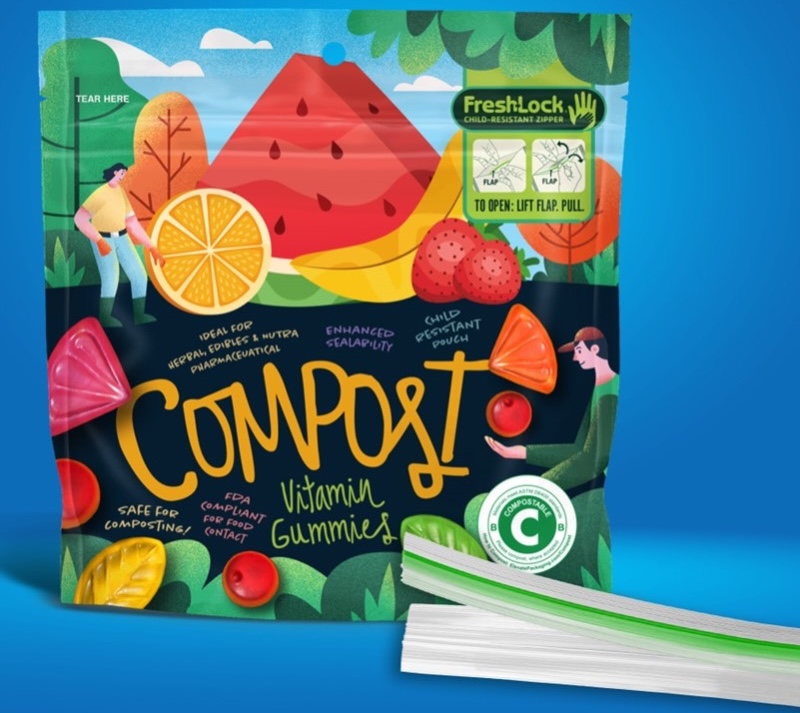

The Fresh-Lock® ergonomic slider allows consumers to easily roll out excess air and simply slide the package shut, keeping moisture out and freshness in. Moving the ergonomic slider ensures that the package is closed, so consumers feel confident after each use. Plus, the smooth design reduces film dimpling, making it a smart option for packagers looking for consistency and reliability for hooded flexible packaging.

If a zipper closure is preferred, broad-field zippers like the Fresh-Lock® double zipper won’t unseal when stored in freezing temperatures. Consumers also appreciate the enhanced tactile feedback of zipper closures, letting them know that they’ve closed the package after each use. Our proprietary Soft Seal® material minimizes end seal leaks and uses less crushing energy making these zippers a trusted option for both packagers and consumers.

A report from the American Frozen Food Institute (AFFI) and the Food Marketing Institute (FMI), found frozen food sales to be almost $57 billion annually. When it comes to waste and those purchases, consumers are understandably concerned, as every package tossed is money lost. As a frozen food packager, you can help consumers waste less money, build brand loyalty, and take part in helping the overall global food waste reduction by using more reliable closures.

Build Brand Reliability with your Flexible Packaging

If your brand is looking to build reliability and reduce waste with your frozen food packaging, contact us to discuss the best option for your needs. Together, we’ll help save your customers money and reduce the global waste impact.

Back to Blog

Back to Blog