Case Study: How Child-Guard® Became a Child-Resistant Solution for Flexible Packaging

The growth of flexible packaging is impressive, and it shows no sign of slowing down. The stand-up pouch in particular is convenient for the consumer, cost-effective for the manufacturer, and offers sustainability benefits.

Along with the expansion of applications for pouches came a demand for increased safety, especially for young children who need to be protected from accessing products containing ingredients that could cause them harm.

That’s why Reynolds Presto® Products Company set out to develop a child-resistant closure within the Fresh-Lock® division. Child-Guard®, also branded as Slider-Guard™, is now showing up on store shelves and is considered by many to be a revolutionary innovation in packaging safety.

The Challenge

Create a child-resistant closure for use on a reclosable pouch or bag in order to improve the safety of this packaging format and help expand the use of flexible packaging as an alternative for a wide range of markets.

The Process

Step 1: Developing a Child-Resistant Slider

"Once the need for a child-resistant closure for flexible packaging was identified, our product development team and technical experts began brainstorming possibilities," says Senior Sales & National Accounts Manager, Todd Meussling.

Meussling was closely involved with the development and testing processes. He says Fresh-Lock® was the right business to take on this challenge.

"A lot of our existing intellectual property, leadership, and experience in the marketplace lent itself to developing a child-resistant closure," Meussling explains. "We already had the basic equipment designed. We have a lot of our own patented technologies to support the product."

A variety of ideas were imagined and discussed. As is usually the case, some were better than others. Meussling says certain initial concepts involved two-piece and multi-component alternatives, which were dismissed early on.

"The more parts you have, the more complexity you add," he says.

The goal was to keep the closure simple for everyone involved. Meussling says Child-Guard® is designed to be relatively simple for pouch converters to add to a bag, simple for product manufacturers to add to many types of filling equipment, and simple for adult consumers to open and close.

The solution that rose to the top was a typical slider involving an additional step to “unlock” the pouch.

Step 2: Product Testing for Child-Resistance

The next phase in bringing Child-Guard® to market involved achieving regulatory standards for approval as a child-resistant closure.

"Meeting child-resistant criteria was paramount. It had to do that, otherwise it didn’t matter," Meussling says.

Official testing involved children under the age of five and older adults between the ages of 50 and 70. The Child-Guard® closure needed to be difficult enough to keep young children from opening it, yet intuitive enough for adults to operate.

Testing Criteria for Children:

A panel of children, including a mix of boys and girls, is tested in an area that’s familiar to them. They are given 10 minutes to open the package and, halfway through, an adult shows them how to open and close the package.

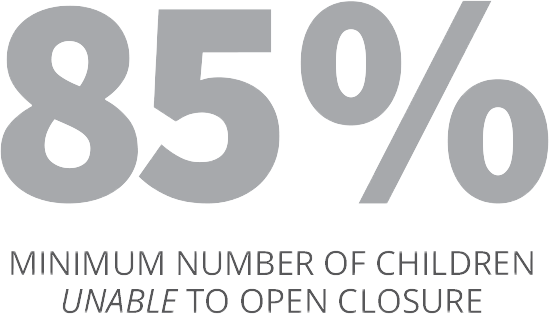

In order for a package to pass the test, a minimum of 85 percent of child participants must be unable to open it before seeing a demonstration, and a minimum of 80 percent must be unable to open the package after seeing the demonstration.

"You have gentle kids who are very easy with the package. Then you have some kids that, frankly, we thought for sure they’d get through that package," Meussling recalls. "There were tough kids who were not afraid to go after it."

At a certain point during testing, kids are told they are allowed to use their teeth. Meussling says he’s surprised some of them didn’t lose a tooth.

"The kids are tough, but the packages are tough, too."

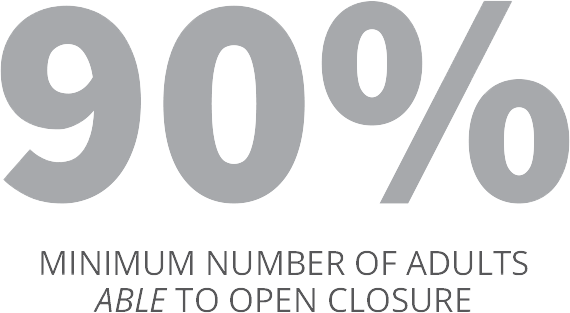

Testing Criteria for Adults:

Making sure adults are able to open a potentially child-resistant package is also part of the testing process.

The panel of adults is given five minutes to open and close the package being tested. A minimum of 90 percent of participants must be able to do so successfully.

In order to help improve the closure’s design, representatives from Fresh-Lock® would sometimes conduct exit interviews with adult test participants. Meussling says this feedback helped to “polish” Child-Guard®’s functionality.

To date, the Child-Guard® closure has met the criteria in all official tests for child-resistance, which allows the closure to be used as a component of a child-resistant flexible package.

"Our closure has been used in multiple tests with a range of companies and film structures, and we’ve been consistently happy with its performance on the test results," Meussling says.

Step 3: Consumer Education

As this innovative child-resistant closure shows up on packaging, it’s crucial that consumers understand how it works.

"Everybody knows what a slider is," says Meussling. "What we were concerned about is that people would just assume it’s one of our typical sliders. They’d try to open it normally, and wouldn’t be able to get into the package. We want to make sure they realize it’s a slider with an extra step because it’s made to be that way."

That’s why Fresh-Lock® launched marketing efforts aimed at consumer awareness. These efforts increase the likelihood that shoppers will be somewhat familiar with the closure when they first encounter it on store shelves or in the home.

"We also work closely with brand managers to make sure proper opening instructions are available on packages for first time users," Meussling says.

A major education initiative was the launch of Child-Guard.com in August of 2016. This consumer-facing website is home to the Child-Guard® brand. It includes informational videos, a blog containing safety tips for parents, and material on brands using the closure.

Fresh-Lock® is also working to inform the public using social media and by networking with online influencers such as popular bloggers who offer parenting and safety advice.

The Results

One of the first industries to take advantage of the safety benefits this child-resistant closure provides is laundry.

Responsible brands like Tide™, ARM & HAMMER™, and HEX™ Performance detergents are applying Child-Guard® and Slider-Guard™ to safely use flexible packaging with laundry packets.

Also known as the soluble unit dose (SUD), this popular product type can now be sold in a stand-up pouch while providing families with an extra layer of protection, which gives parents time to respond if children try to access the product.

"I think we’re going to see the use of the water soluble unit dose continue to expand outside laundry and dishwasher," Meussling says. "I could see that growing into a broader range of household products."

Other industries Meussling sees taking advantage of a child-resistant slider include pharmaceutical, agro-chemical, and pool chemicals.

Meussling says the best part about bringing this packaging solution into reality is knowing that it’s making a positive difference in the world.

"I’ve been in packaging for 25 years. What excites me about this is the way it’s helping society. If one of these closures helps to prevent an injury, it’s all worth it."

Child-Guard® is there to make flexible packaging safer while helping to meet potential regulatory requirements. If you have questions about Child-Guard®, child-resistant closures, or any of the products available from Fresh-Lock®, please contact us today to learn more.

Back to Blog

Back to Blog