Fresh-Lock’s Zipper Spool Programs: Sustainability and Efficiency for Flexible Packaging

Eco-friendly manufacturing practices do more than give companies something to brag about. Sustainability and efficiency go hand-in-hand, leading to cost savings and a cleaner planet.

That’s why Fresh-Lock® Slider Zipper has been offering unique zipper spool recycling and reuse programs since 2009. We’re helping packaging converters and manufacturers reduce waste and save money when producing flexible packages with Fresh-Lock’s zippers and slider closure systems.

These initiatives are provided at no cost to our customers, and offer credits towards future purchases from Fresh-Lock®.

Let’s take a closer look at how these two programs work …

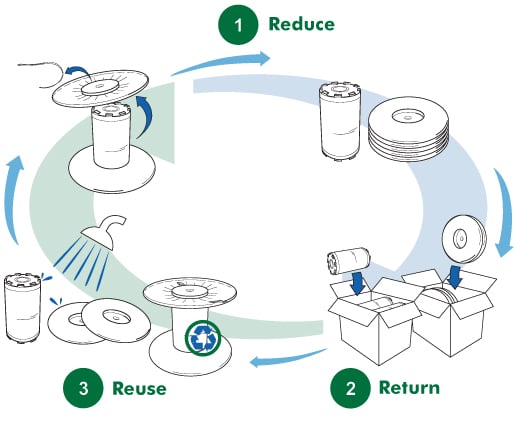

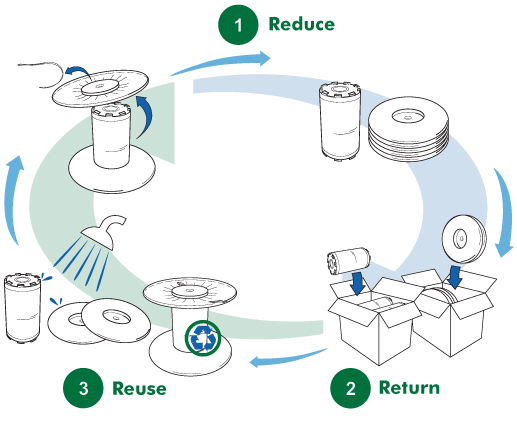

The Zipper Spool Reuse Program®

Zippers are shipped to converters on large plastic spools, which hold the product, allowing it to be fed into equipment and applied to the pouch. Instead of sending the spools to the landfill, the Zipper Spool Reuse Program® allows converters to send them back to Fresh-Lock®. Wondering about shipping costs? We have that covered.

However, the benefits don’t end there. Converters and manufacturers also receive a $1 credit for every spool that’s returned, which can be used toward future product purchases.

Fresh-Lock made all of this possible after developing reusable modular spools, which can easily be broken down and sent back in their original shipping cases. The spools are inspected and washed before going back into the supply chain. It’s a simple but groundbreaking concept, which is the first of its kind in our industry.

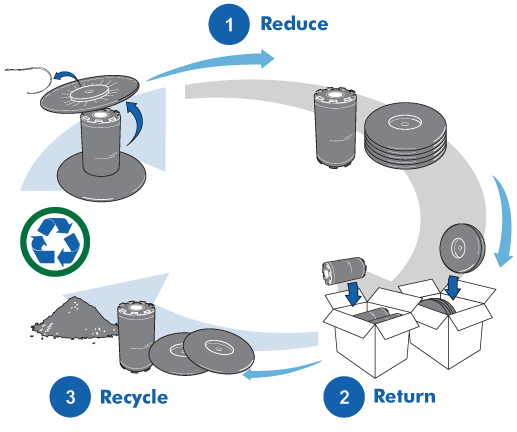

The Zipper Spool Recycling Program®

There are some situations in which converters are unable to reuse spools. That’s why Fresh-Lock® also created a program that recycles zipper spools.

Participating converters are still keeping waste out of landfills as these spools are broken down, recycled, and turned into new single-use zipper spools. The process for returning these spools in the Zipper Spool Recycling Program® is the same as the reuse program, and you will incur no shipping costs because they’re covered by Fresh-Lock®.

Making a Positive Impact

Since the launch of these programs in 2009, Fresh-Lock has supported the removal of nearly 6 million pounds of High Impact Polystyrene (HIPS) from the waste stream, diverting this material from landfills and reusing the spools in new shipments of our zippers. The programs are also helping packagers reduce greenhouse gas emissions and electricity usage.

Our efforts helped Jack Link’s® achieve a zero-landfill plant in Alpena, South Dakota. The beef snack manufacturer reuses an estimated 30,000 pounds of HIPS per year.

“This is part of a comprehensive sustainability program at Jack Link’s,” Thomas Myers, director of corporate sustainability for Jack Link’s® told Packaging Strategies in 2014. “At Jack Link’s, we strive to be great stewards of our natural resources.”

The Zipper Spool Reuse® and Zipper Spool Recycling® programs can also help manufacturers avoid fees. For example, before implementing our program, Johnsonville was forced to pay tipping fees in order to dispose of unwanted spools. Read more on the Package Design magazine website.

Converters and brands alike trust Fresh-Lock® Slider Zipper for high quality reclosability. Did you know 89% of slider zipper packages sold in North America have our closures on them? Find out why so many rely on Fresh-Lock® to add value to their flexible packaging. Explore our selection of zippers and sliders to find the right solution and contact us today to learn more and discover ways we can help meet your packaging needs.

Back to Blog

Back to Blog