Flexible Packaging for Chicken: Product Quality and Sustainability

The popularity of home cooking is undeniably growing.

While this trend of cooking at home was largely built upon necessity, consumers are continuing to cook at home because of the benefits they’ve seen to their health and finances, according to food industry firm HUNTER. Additionally, the National Chicken Council notes that 50% of chicken eaters in the U.S. have eaten it more than any other protein during the pandemic.

Meeting this demand has chicken brands and packagers seeking ways to ensure a strong consumer experience in this market. Luckily, improved technologies in reclosable flexible packaging have offered ways to help maintain the quality of chicken products longer – creating more confidence in consumers and more options for packagers and producers.

“Consumers should have a positive experience from the first time they use their chicken product to the last use,” said Gianni Holzem, Fresh-Lock® Commercial Sales Director at Reynolds Consumer Products. “Our efforts are all about maintaining that experience the consumer had the first time they opened the package.”

Pairing Closures with Flexible Packaging

While consumers purchased more fresh foods during the COVID-19 pandemic, they spent less time shopping in stores. That means people are keeping more food on hand or ordering from grocery delivery websites. Insider Intelligence’s Online Grocery Report says more than half of American consumers will buy groceries online by the end of 2024.

Ensuring a product will survive delivery and remain protected within the freezer or refrigerator is key. Whether a package is damaged during delivery or has simply been opened by the consumer, oxidation – the chemical process that begins to break down food quality – begins as soon as oxygen can enter the package.

Reclosable flexible packaging with Fresh-Lock® technology offers durability and can help slow oxidation when combined with proper refrigeration and freezing. Moisture retention is important for maintaining the texture and quality of chicken. Whether the consumer has chosen frozen, processed, or deli chicken, the right closure paired with an appropriate film material enables the package to be resealed again and again for the freshest experience.

Audible/tactile closures, or those that make a clear and reassuring sound when opening and reclosing, also work to help build that confidence. This can be particularly welcome when parents are cooking with children and teens, as they’ll know whether or not a package is closed properly or whether it’s been closed while waiting inside the refrigerator.

“High-quality reclosable flexible packaging can create a sense of security in the chicken product and helps creates a feeling of confidence in the decision to buy it again,” Holzem said.

Fresh-Lock Closures for Chicken Products

Several Fresh-Lock® products have proven to be popular with chicken brands.

Fresh-Lock® Pre-Zip closures feature an easy, reliable open and reclose perfect for multi-use products. Pre-Zip Style 356 includes a peelable seal for tamper evidence and hermeticity, and all Pre-Zip styles provide a broader operating window than comparable products for greater flexibility across a wide range of applications.

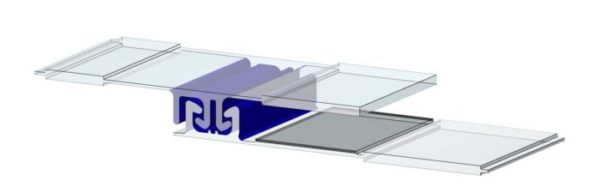

Fresh-Lock® zipper styles 356

Fresh-Lock® Zipper Top style 8253 offers a recyclable closure option that provides both consumers and packagers with sustainability advantages to contribute to a circular economy. The strong seal helps to reduce food waste when properly reclosed, and Zipper Top forms the top of a package in a proprietary process, which is more sustainable than manufacturing processes of similar closures in market.

Fresh-Lock® Zipper Top™ 8253

Enhancing Sustainability in Packaging

The Fresh-Lock team is committed to developing greater sustainability throughout the lifecycle of reclosable flexible packaging products for chicken, starting with the manufacturing process.

The Fresh-Lock® Green Spool Program allows for zipper spools to be sanitized and reused or to keep them out of the landfill. Our reusable, modular spools can be broken down and returned for a credit toward future Fresh-Lock purchases. Or, for companies that can’t take advantage of reusable spools, the Fresh-Lock team can recycle them into new, single-use spools, allowing producers to still take advantage of an environmental benefit.

A compatible film and zipper combination also reduces waste within the production process, creating more efficient output. All of these efforts result in less waste for manufacturers and fewer resources consumed which can also save time and money.

Flexible Packaging for Chicken

When consumers have a positive experience with the safety and quality of their product – which includes their holistic experience with packaging – they will be more likely to make a repeat purchase.

“The packaging and zipper must work together,” Holzem said. “You need some way to maintain that food quality and to create a good experience for the consumer and producer overall. That’s really what we do.”

We work closely with brands and makers of film to determine how to create the best consumer experience. If you don’t see a current closure option that fits your needs or don’t know what would work best with your chicken product, please contact the Fresh-Lock team today, and we will work with you to develop the best solution for your needs.

Back to Blog

Back to Blog